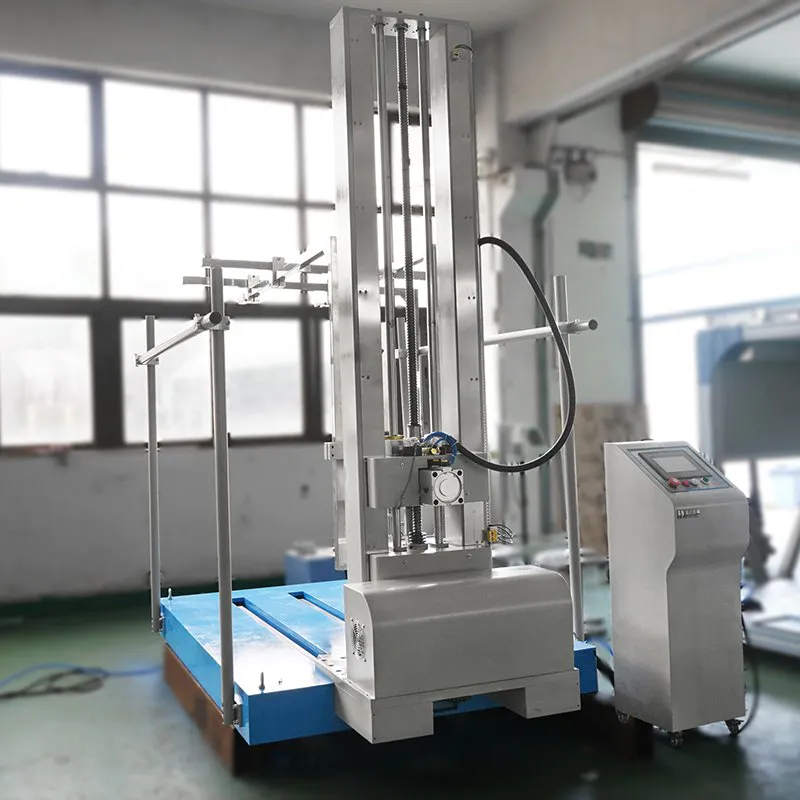

Zero Drop Tester is mainly used to evaluate the damage by drop impact on the package during actual transportation, loading and unloading, and to assess the impact strength of the package and the rationality of the package design during the transportation process., especially for drop test of larger packages.

HD-A520-3 Drop Tester is mainly used to test angles, faces and corners of package.

This machine can freely set the drop height, which can make the sample fall freely instantly.

Loading

Simulate the degree of drop impact during loading

Transport

Simulating the effect of falling impact in the process of automobile transportation

Handling

Simulating the impact strength of the package in the process of handling

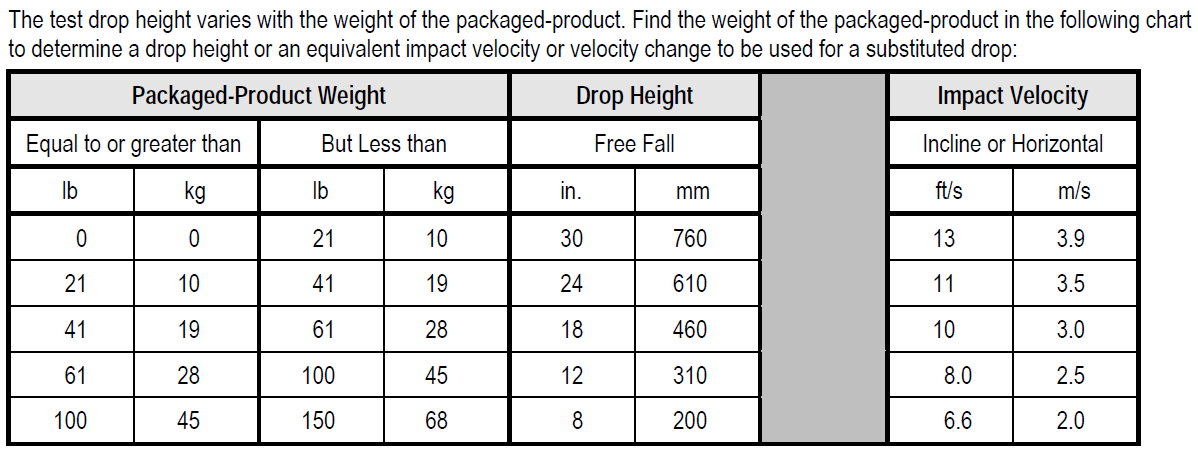

Design Standatd:

ISTA, ISO 2248-1985, GBT 4857.5-92

العربية

العربية