Computer Control Hydraulic Universal Testing Machine

1.Structure introduction:

It is mainly used to execute the tension, compression, bending, shearing etc. test for metal materials. Attached simple accessories and devices, it can be used to achieve many kinds of mechanical performances.

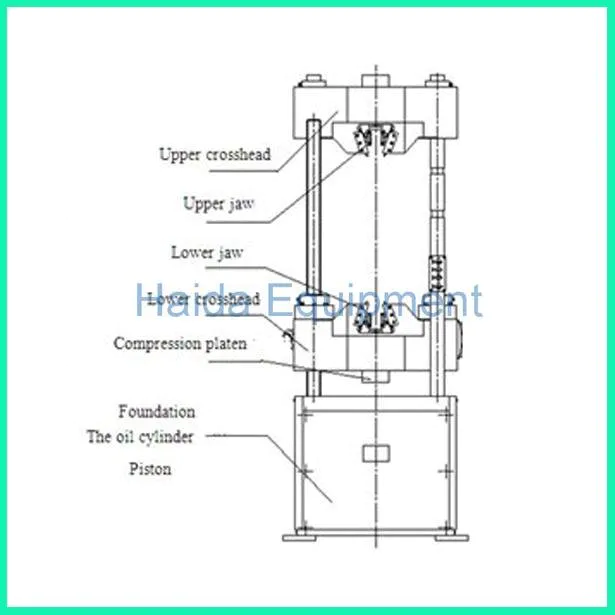

The oil cylinder is at the bottom of the load frame, tension space is at the upside of the load frame, compression and bending space is between lower crosshead and working table. The lower crosshead is driven by motor through decelerator, chain transmission device and screw pair, so realize the adjustment of testing space.

The machine adopts oil pressure transducer to measure load, use computer control &display load,

2.Main specifications:

Max. Test load: 300KN

Load range: 6KN-300KN

Relative error of indicate value of load : ±1%

Max. Ram stroke: 250mm

Max. Tensile space: 800mm(including piston stroke)

Max. Compression space: 700mm(including piston stroke)

Display: Computer control and display

Tensile grips for round specimen : φ6-φ26mm

Tensile grips for flat specimen: 0-15mm

Distance for two columns: 500mm

Upper and lower platen size: 200x200mm

The span of bending: 450mm

Width of bending roller: 140mm

Dia. of bending roller: 30mm

Clamping mode: Hydraulically

Transducer: load cell

Deformation measuring: YYU–10∕50

Dimensions of load frame : 990×600×2435mm

Dimension of controller : 1140×700×930mm

All weight: 2800kg

3.Load frame

Load frame photo design

● Rigid four column construction &compact design

● Dual workspace design : upper for tensile test , lower for compression and bending tests

● Movable lower crosshead providing exceptional easy operation

● Accurate force measurement through precision load cell

● With open hydraulic wedge grips for easy change of inserts and specimen loading

● Integrated displacement photoelectric encoder

● Cylinder mounted at the bottom of the machine

Picture of principle of hydraulic pressure

Characteristic of principle of hydraulic pressure

● Adopt import high pressure pump, lower noise, steady pressure

● Dynamical Systems and console integration design, easy to operate, save testing space

● The surface by spray treatment, appearance beautiful

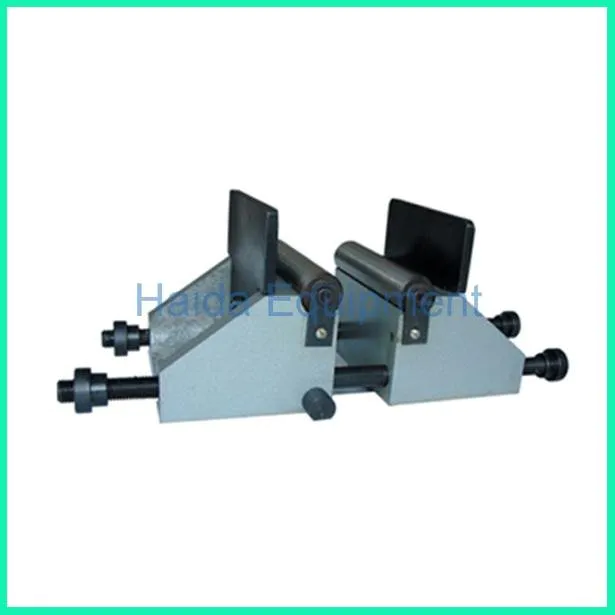

Main standard accessories:

Upper and lower platen for compression 200x200mm one set

Extensometer one set

Round specimen grip for tensile φ6-φ26mm one set

Flat specimen grip for tensile 0-15mm one set

Bending accessories one set

High accurate load cell one set

High precision photoelectric encoder one set

Measuring the displacement

High pressure pump one set

Proportion Valve one set

Electro-hydraulic servo valve one set

Optional accessories

Shearing accessories one set

Annex

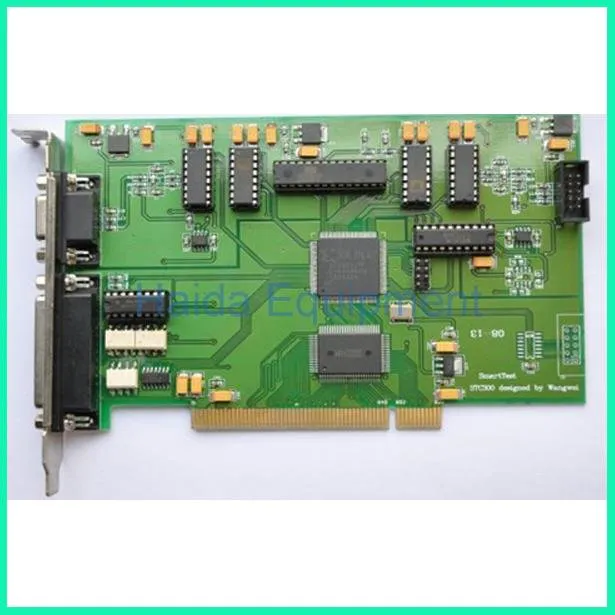

Brief introduction STC300 Control System

STC300 all-digital closed-loop control system has many advanced features and technological innovation, mainly reflected in:

● To achieve the test force, the specimen deformation, piston displacement and testing process, the four closed-loop control;

● Data acquisition system is composed of 4-way high-precision 24-bit A / D converter channels. The maximum resolution of up to 1 / 300000, full regardless of section;

● Use BB, AD, Xilinx and other original brand-name integrated device, all-digital design;

● Meet the PCI standard, computer and installation of automatic identification,;

● Electronic measurement systems without analog components such as potentiometers to ensure interchangeability for easy maintenance and replacement。

Brief introduction MaxTest software

MaxTestsoftware In line with GB228-87, GB228-2002 and other relevant provisions of more than 30 national standards

● Computer software system is highly integrated, stable performance, easy to adjust and so on. In real-time experimental data can be collected, the experimental realization of real-time dynamic display characteristic curves, test data files can be used with Access database or SQLserve way to save large databases to facilitate the sharing of resources to achieve customer and network management, and the user’s re-analysis. For a variety of user-defined reports word2000, the software can easily access to solve the different users or the same user at different times of the trial reports has different needs problems. The software can handle test force, displacement, time, raw data and the resulting derivative curve.。

● Protection function: This machine has two kinds of software and mechanical limit conservation, exceeds the maximum load can be automatically shut down the ratio of dynamic setting; with the over-current, over voltage, overload and other protection functions.。

● For the load channels can be automatically labeled and intuitively easy。

● Batch test can achieve the curves at different levels show。

● The software enables the user to customize the speed settings to adjust the speed of the computer. Can also achieve high-precision calibration of the speed at any time adjust the speed of section and coding 。

● Monitoring the testing process: the course of the experiment the test force, displacement, curves and other parameters can be realized real-time display 。

● Software rights management features classification: In order to improve software and data security, the software can set different passwords to protect data。

● The results reproduce features: the coexistence of trial operation is complete, after-hours, according to user needs at any time in the future to open and re-analysis of test data。

● According to the user can choose load ~ time 、load ~ displacement 、displacement ~ time curve to carry out testing and data display, storage, analysis and printing。

● Curve point by point traversal function: by mouse click on the force and deformation curves of the value of each point in order to achieve a variety of parameters.。

●The comparison function: You can simultaneously observe the number of experimental curves, multiple curves can be superimposed, local amplification to achieve the characteristics of the sample to be analysis。

● Power Interface: Force-channel interface and test software according to user needs with a variety of sensors, and can be calibrated, modify parameters and the normal test。

● Data sampling frequency: You can choose according to the user test requirements of high-speed sampling frequency。

العربية

العربية