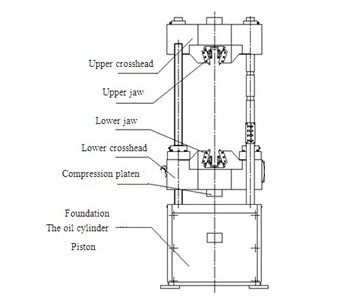

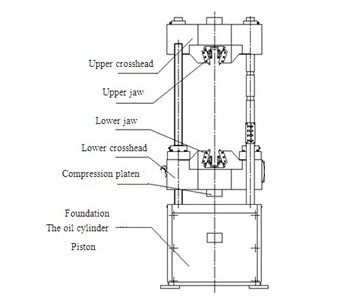

Hydraulic Universal Testing Machine with underneath type oil cylinder and four columns structure is mainly used to do tension, compression, bending, shearing test for metal materials, non-metal material. It is applied for fields of metallurgy, construction, light industry, aviation, aerospace, materials, universities, scientific research units, etc.

This universal test machine uses the motor to drive screw to move fixtures. Fix sample between upper and lower fixture and pull sample by the upper fixture upward with specified speed. The load cell connecting with upper fixture will sense the force and then convert it into voltage sign to the display screen. Force value will be displayed automatically on the screen.

Applications

Deformation under defined load: Test deformation under defined load of tested sample

Load under defined deformation: Test load under defined deformation of tested sample

Software can issue report with results for max. force, elongation, tensile strength, peel strength, tear strength, compression strength, etc.

This Hydraulic Universal Testing Machine can do different test as per customer requirement such as peel test, tear test, compression test, bend test with different clamps.

Design Standard(inculding but not limited to...)

Tensile Test: ASTM D882 ASTM D 638 / ISO 527-1/2

Bend Test ISO-178 / ASTM D 790

Tear Test:ASTM D 624

Peel Test : ASTM D 3330

Compression Test : ASTM D 659

others...

Item

| Description

|

Max. load

| 300KN

|

Load range

| 6KN-300KN

|

Load accuracy

| ±1%

|

Elongation resolution

| 0.01mm

|

Piston stroke

| 250mm

|

Max. piston stroke speed

| 50mm/min

|

Elongation accuracy

| ±1%

|

Max. Tensile space

| 300mm(excluding piston stroke)

|

Max. Compression space

| 250mm(excluding piston stroke)

|

Display mode

| PC

|

Clamping mode

| Hydraulic

|

Operation mode

| Manual

|

Flat sample thickness

| 0-15 mm

|

Clamping width

| 70mm

|

Round sample diameter

| Φ10-φ32 mm

|

Compression plate size

| 170*170mm

|

Load frame dimensions

| 900*750*2200mm

|

Oil source dimensions

| 1200 x 550 x 1100mm

|

(universal testing machine)Related Products:

|

HD-609/604

| 2000 kg (20KN)Max. Force / for Tape, rubber, plastic, textile, waterproof material, wire and cable, net rope, wire, metal rod, fiber, metal chain, metal plate and other materials

|

HD-611

| 10T (100KN) Max. Force / for waterproof material, wire and cable, net rope, wire, metal rod, fiber, metal chain, metal plate and other materials

|

HD-615

| 5000 kg (50KN) Max. Force / for textile, waterproof material, wire and cable, net rope, wire, metal rod, fiber, metal chain, metal plate and other materials

|

HD-B616

| 20KN-1000KN (Hydraulic) load range / for waterproof material, wire and cable, net rope, wire, metal rod, fiber, metal chain, metal plate and other materials

|

Want to know more details,please contact us "manager@qc-test.com"

|

Machine Picture:

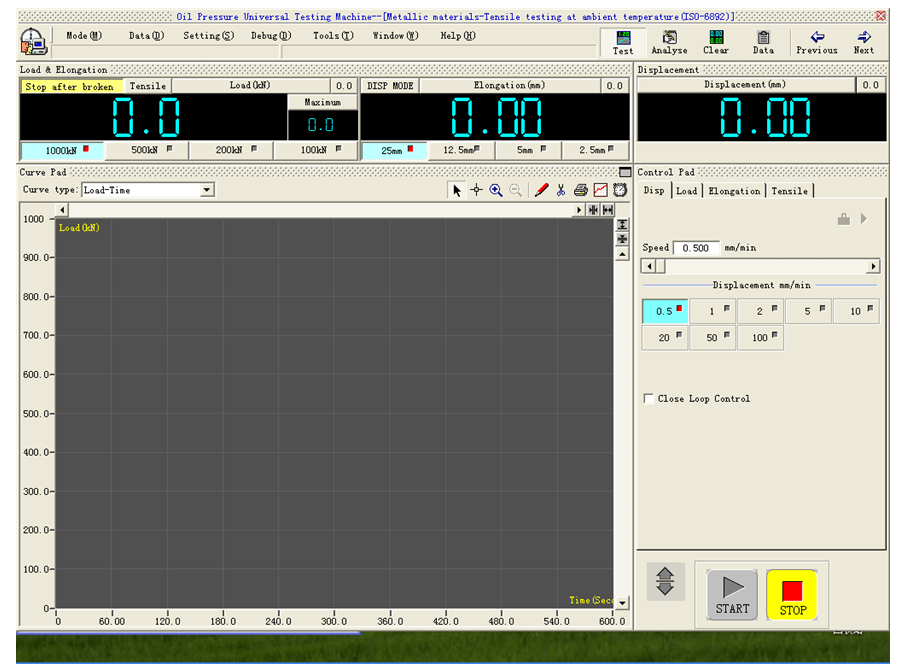

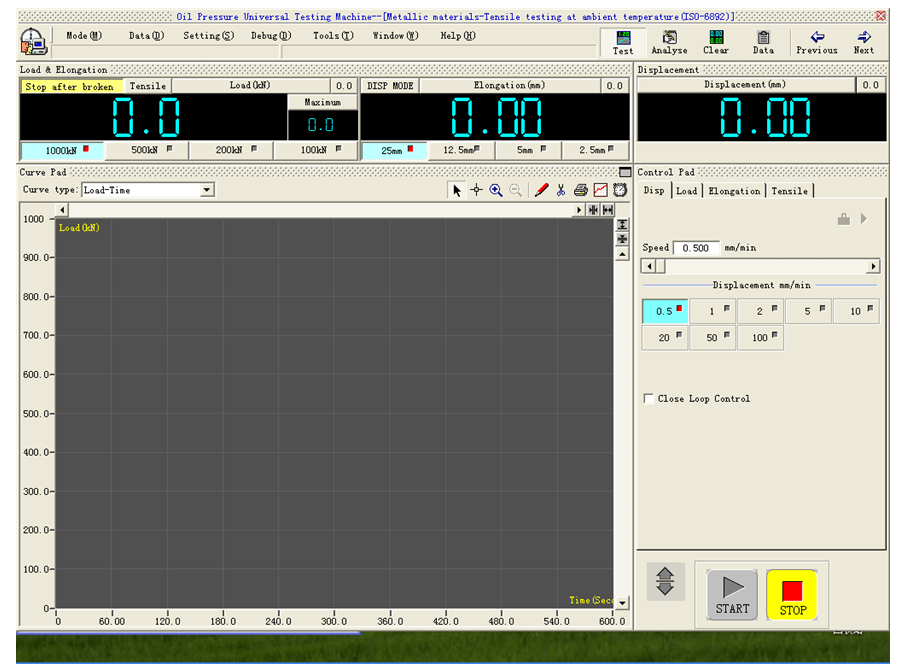

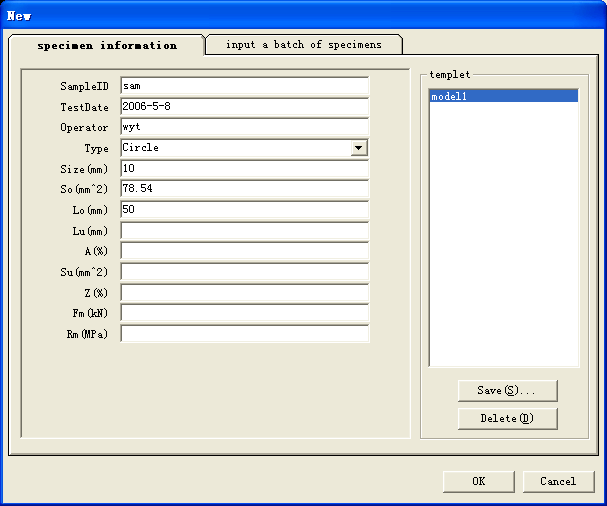

Software:

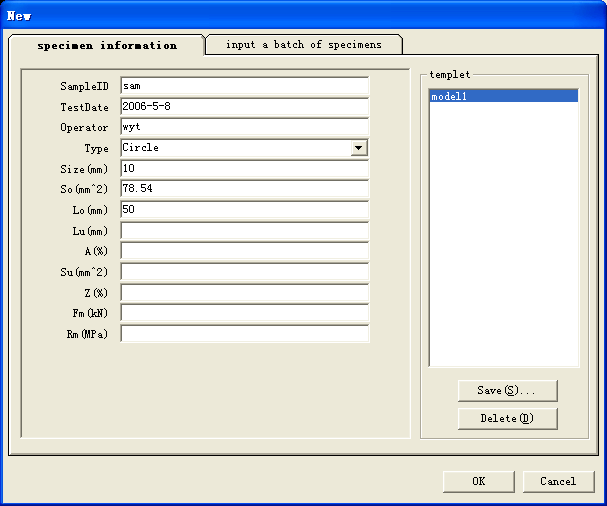

The TM2101 software is designed purposely for computer controlled electronic universal testing machine, used for tension, compress, bend, shear, tearing andpeel test. With the personal computer and interface plate, it could collect, save, process and print test result. Further it can calculate multiple parameters, i.e. maximum force, yield strength, average peel force maximum deformation, yielding point and elastic modulus; this system is featured in curve process, multi-sensor support, image interface, flexible data process and powerful system function.

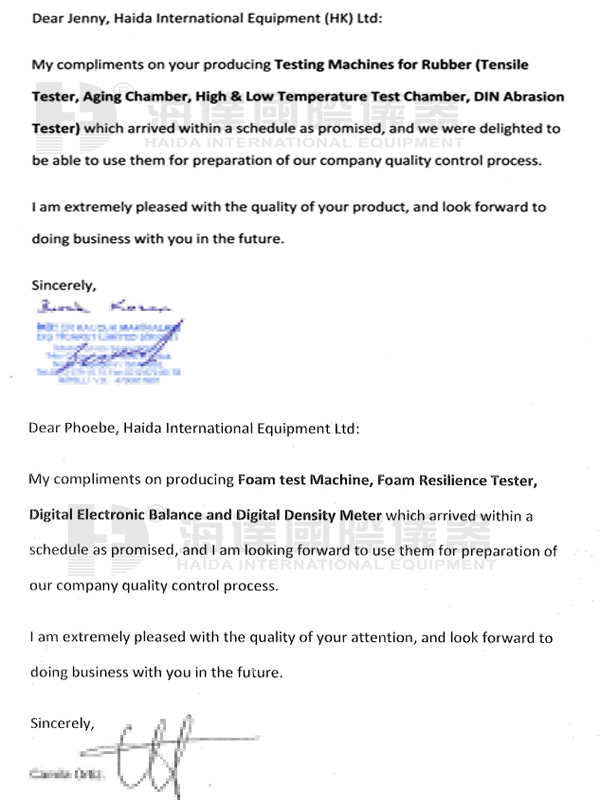

Customer feedback:

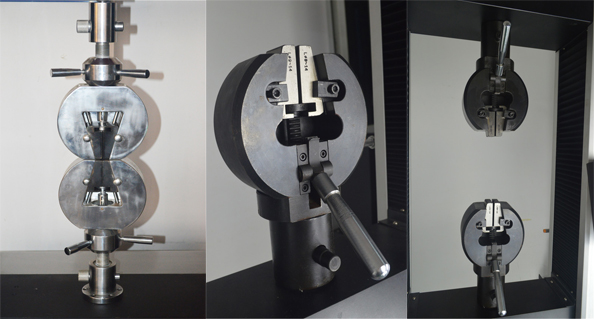

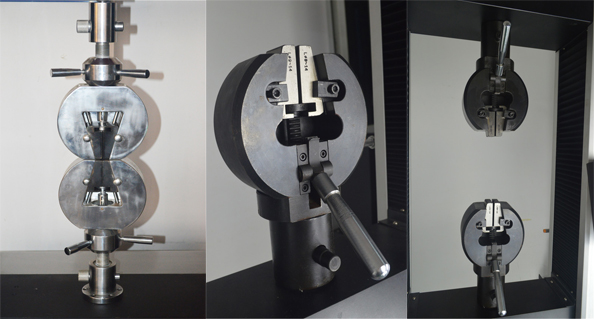

Parts Picture &Fixture:

Lab Room:

Part Of Our Partner Customer:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.

1. Pre-service

--24 Hours online service for your consult.

--Help choose right model,and a series of service,person,advise.

2. Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request:

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

3. After sale service :

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Free change for some parts

--Remote control technical consult

--Free installation DVD

--Maintenance plan

4,Commitment:

We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

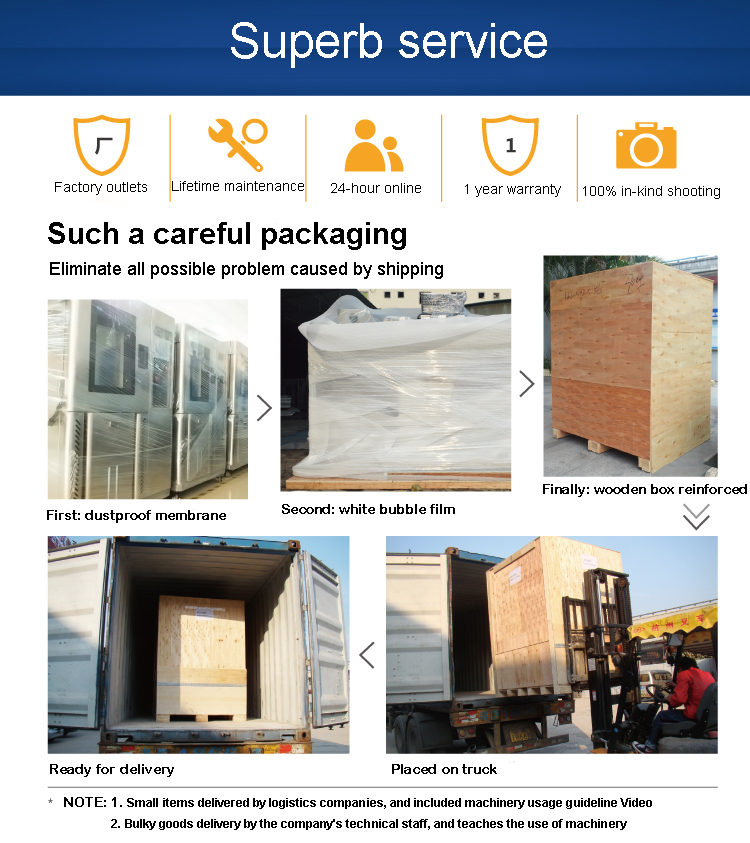

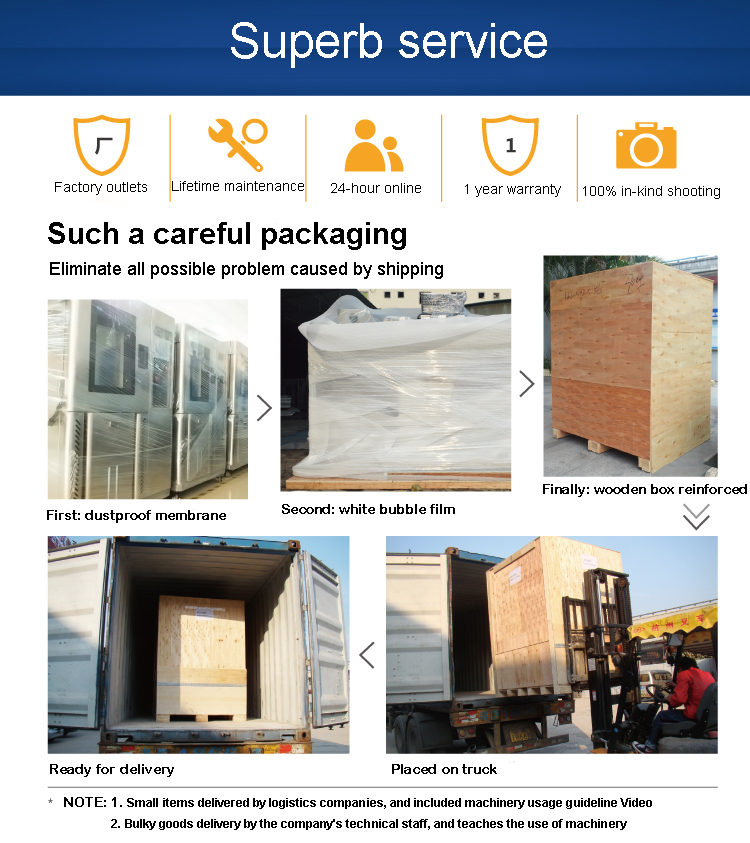

5,Good Packaging:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

Packaging & Shipping:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

FAQ:

Q:Are your company a trading one or a factory?

A:Factory + trade (integration),More than 12 years focusing on test equipment field,6 years exporting experience.

Q:What about the warranty with after - sales services?

A:The testing machine is guaranteed for 12 months by HAIDA,we can help you to repair your problem controller freely,even it's not from our factory. After the warranty, the professional aftersales service team will provide perfect technical support and help guests solve problems encountered while using our product, handles guest problems and complaints in a professional and timely.

Q:What about the product' services and quality?

A:Each equipment must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. We can arrange engineer to train the operation of equipment to customer’s company when you need. products are widely recognized and trusted by users.

A :Considerate Service Different countries plugs, manually change the-voltage from 110V to 220V, insurance indicator.

How to Contact Us?

Please Send your inquiry Details in the below for our quotation,Click "Send" Now!

العربية

العربية