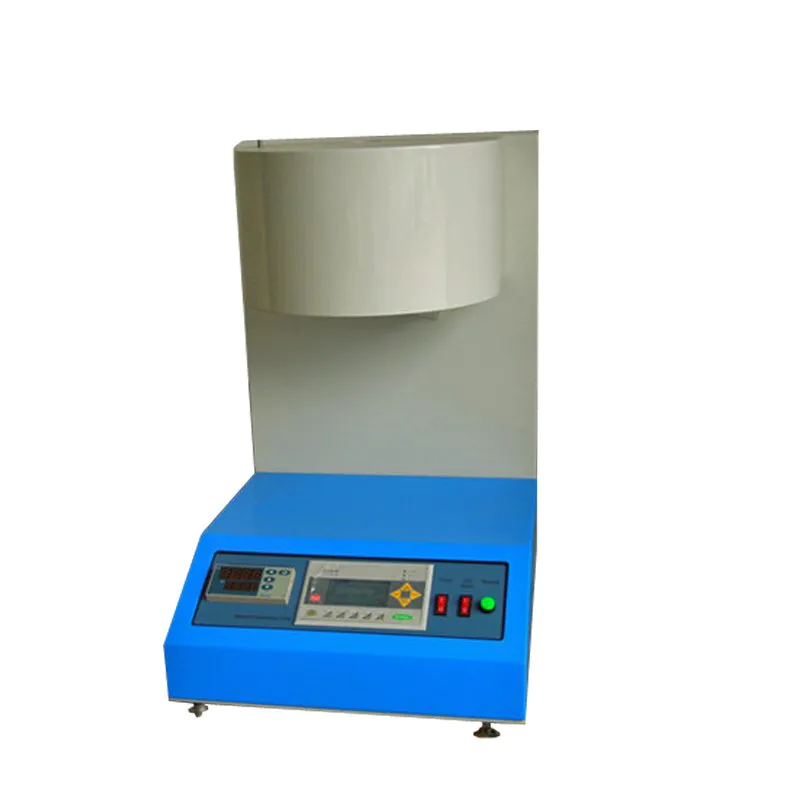

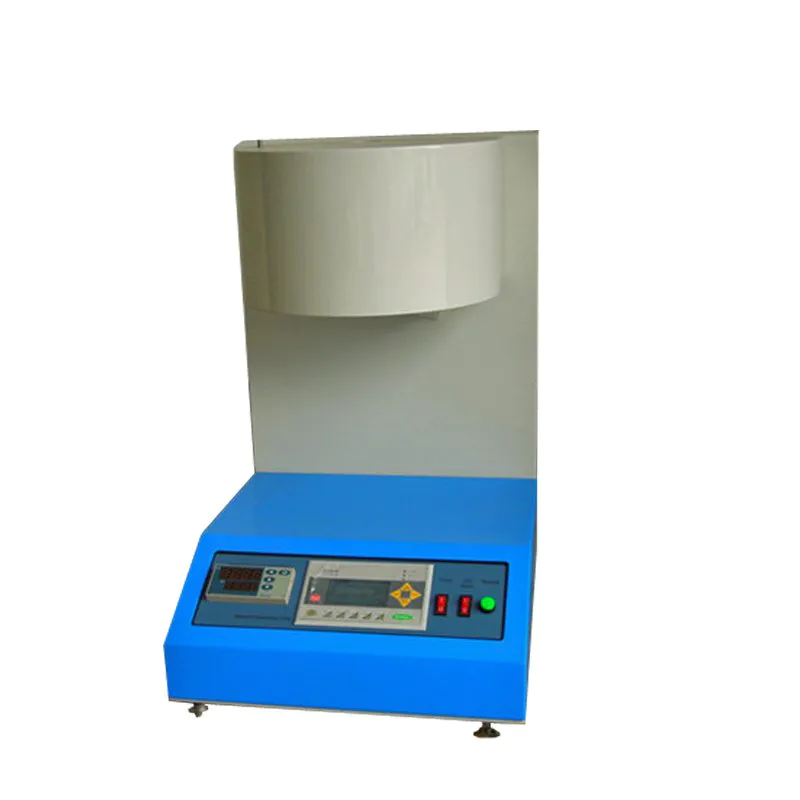

Melt Flow Rate Testing Equipment

Brief introduction

1.Purpose of Melt flow rate testing equipment:

Melt flow rate testing equipment(also known as melt index meter) was measured under certain conditions thermoplastic melt flow rate of the special equipment. With the determination of melt flow rate MFR, measured melt volume rate MVR, measured melt density ρ, measured melt flow rate ratio FRR and other functions, this machine high precision temperature control, key parts nitriding treatment, high strength and hardness , small deformation accurately measure the flow rate which provides a good condition.

2.Principle of Melt flow rate testing equipment:

Thermoplastic melt flow rate (melt index) is plastic at a temperature and load, the melt every 10 minutes through a standard capillary die quality or melt volume, with MFR (MI) or the MVR value, which can distinguish thermoplastic adhesive in the molten state flow characteristics. For thermoplastics and chemical fiber raw materials, quality assurance of products and other products of great significance.

3.Standard of Melt flow rate testing equipment:

This instrument reference standards: ISO 1133, ASTM D1238, JIS-K72A, GB/T3682, JB/T5456, JJG 878

4.The main technical parameters of Melt flow rate testing equipment:

Measuring range :0.1-800 .00g/10min (MFR) 0.1-800.00 cm3/10min (MVR)

Temperature range: room temperature -450 ℃

Temperature accuracy: ±0.5 ℃

Timing accuracy: 0.1S

Displacement accuracy: 0.01mm

Load: full load

Material cutting modes: manual, time control, automatic

Barrel diameter: 9.550mm ± 0.025mm

Barrel Length: 160mm

Die: made of tungsten carbide, length: 8.000mm ± 0.025mm diameter: 2.095mm ± 0.005mm

Power: 0.45KW Power supply: AC220V, 50Hz

Instrument Size: 400mm × 500mm × 600mm

Instrument Weight: 65Kg

5.Instrument structure

Melt flow rate testing equipment consists of a cylinder, the piston rod, die, temperature control system, load, automatic test bodies and automatic cutting and other components. The figure below shows an external view of the product.

1), barrel

Using nitrided steel materials, and after nitriding production, Vickers hardness HV ≥700.

2), the rod (rod)

Using nitrided steel materials, and after nitriding production, Vickers hardness HV ≥600, the head smaller than the barrel diameter evenly 0.075 ±0.015mm, top with an insulating sleeve, the rod and load insulation. In the feed rod with two engraved lines 30mm apart as a reference mark, their position is this: When feeding head under the top edge of the die apart 20mm, the tag line coinciding with the barrel mouth flat (see Figure 2).

3), the die

Die Φ2.095 ±0.005mm, Φ1.180 ±0.010mm (non-standard configuration) Vickers hardness HV ≥700.

4), the temperature control system

The system uses for platinum resistance temperature sensor, AL808 control instruments as a temperature controller, which uses PID control, can automatically compensate for supply voltage fluctuations and ambient temperature influence on the temperature control.

5), the load

Load is the weight and quality of the material and rod assembly. The quality and test load weight distribution tables:

|

Load

|

combination weights (g)

|

|

325

|

T-type weight rod assembly

|

|

1200

|

325+875

|

|

2160

|

325+875+960

|

|

3800

|

325+875+960+1640

|

|

5000

|

325+875+960+1640+1200

|

|

10000**

|

325+875+960+1640+1200+2500+2500

|

|

12500**

|

325+875+960+1640+1200+2500+2500+2500

|

|

21600**

|

325+875+960+1640+1200+2500+2500+2500+2500+2500+2500+1600

|

* Mass rod assembly, the quality of the positioning sleeve is not included.

** The load will be charged with weights.

6.Our company

Introduction:

HAIDA INTERNATIONAL is a professional manufacturer of various kinds of testing equipments over 24 years. HAIDA products are widely used in paper products, packaging, ink printing, adhesive tapes, bags, footwear, leather products, environment, toys, baby products, hardware, electronic products, plastic products, rubber products and other industries, and applicable to all scientific research units, quality inspection institutions and academic fields.

7.After-service

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation manual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer;

العربية

العربية