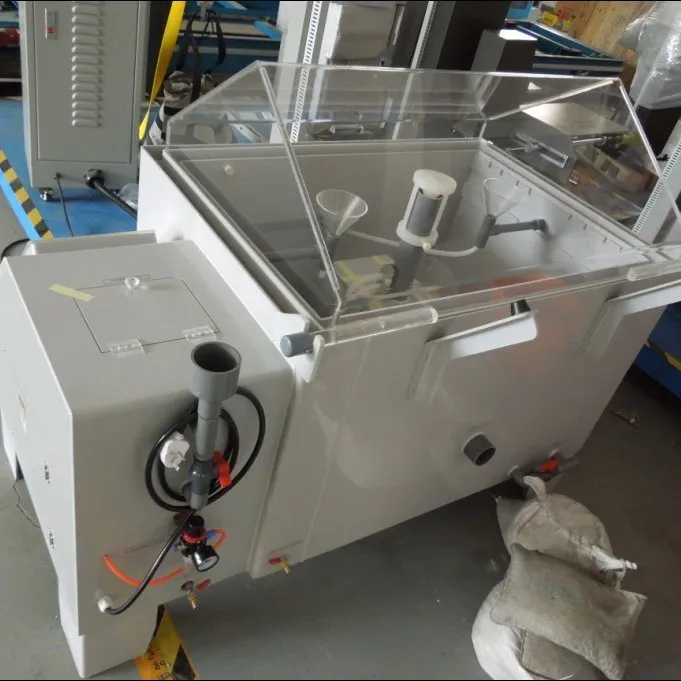

Salt Spray Corrosion Testing Equipment

Salt Spray Test Chamber Video

Salt Spray Test Chamber Video  salt spray test chamber brochure

salt spray test chamber brochure

Specifications

Salt Spray Corrosion Testing Equipment

1 . Durable hard PVC construction ;

2 . reservoir with mixing system on stand

Introduction:

Salt Spray Corrosion Testing Equipment is the use of salt spray corrosion way to detect corrosion, respectively, the reliability of the sample, salt spray refers to the atmosphere by diffusion system composed of tiny droplets of salt, artificial environment of three anti-series one of many companies need to simulate the destructive product of marine climate surrounding the product caused by salt spray chamber so the line should run.

Features:

1. Local temperature and humidity inside and outside the box are used for A-level gray high-corrosive PVC, for salt spray, copper acetate, and other test specifications Test

2. It uses the A-level German imports of gray PVC material.

3. It uses sophisticated Class A gray PVC material designed "V" shape long, products tested by the 15 ° -30 ° angle be adjusted.

4. It uses a 5mm thick transparent imported high toughness PVC board, bending method designed to cover 100 degree ridge-type transparent with power failure memory function of time, so after the original call time to complete the remaining time of the experimental work, with a double over-temperature protection, water shortage warning, ensure safety

5. According to JIS, ASTM, CNS, GB standard parameter setting operation.

Experiment method

GB / T2423.17-2008 salt spray test method

GB / T 2423.18-2000 "basic procedures for electric and electronic products Test Ka"

GB / T10125-1997 Corrosion tests in artificial atmospheres - salt spray test _

GB / T10587-2006 salt spray test chamber technical conditions

GB10593.2-1990 electric and electronic products environmental parameters measurements

GB / T1765-1979 Determination of resistance to humidity, salt spray, weather resistance (artificial acceleration) of the film prepared test

Specifications :

Model | HD-E808-90 |

Internal Size (W*D*H) | 900*600*500mm |

External Size (W*D*H) | 1410*850*1200mm |

Equipment Material | P.V.C rigid plastic plate, thickness 8mm |

Sample tray | Diameter 10mm glass fiber rod, anti-rust V-shape plastic steel to make sure sample in 15~30 degree inclined |

Temperature Range | Room temperature ~ 55℃ |

Temperature Fluctuations | ≤±0.5℃ |

Temperature Uniformity | ≤±2℃ |

Temperature Precision | ±1℃ |

Spraying method | Continuous and Periodic spray type |

Test Chamber Temperature | Salt Spray Method (NSS ACSS)35±1℃

Corrosion-resistant Testing Method (CASS) 50±1℃ |

Saturated air Barrel Temperature | Salt Spray Method (NSS ACSS)47±1℃

Corrosion-resistant Testing Method (CASS) 63±1℃ |

Brine Temperature | 35℃±1℃ |

Spray Quantity | 1.0~2.0 ml / 80cm2 / hr |

PH value | Salt Spray Method (NSS ACSS6.5~7.2)

Corrosion-resistant Testing Method(CASS)3.0~3.2 |

Lab Volume | 270L |

Brine Tank Capacity | 25L |

Multiple Safety Protection Devices | Current discharge protection, over pressure protection, over temperature protection, over load fuse protection |

Accessories | Testing Salt/ Measuring tank/Nozzle Equipment x 1 set |

Air source | 1HP Air pump (provided by buyer) |

Test criteria | ASTM B117-08, ISO 9227... |

العربية

العربية