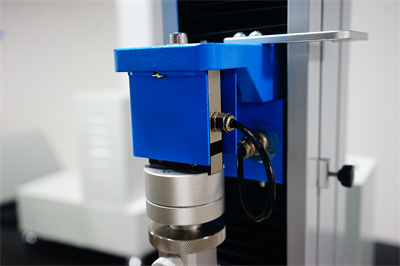

HD-B609-S Computer Servo Tensile Test Machine, is professionally specialized in plastic film, composite, soft packaging materials, plastic hose, adhesive, adhesive tape, medical adhesive, medical device, release paper, protective film, composite cover, metal foil, diaphragm, backboard material, non-woven fabric, rubber, paper and other products of tensile, peeling, deformation, tear, bonding, puncture force, opening force, low speed unwinding force, pull force and other performance tests.

Diaphragm

Panking Tape

العربية

العربية