PRECISION TESTING INSTRUMENT Phone:+86-13602361535 E-mail:manager@qc-test.com

Haida Products

- ISTA Series Test Equipment

- Battery Test Equipment

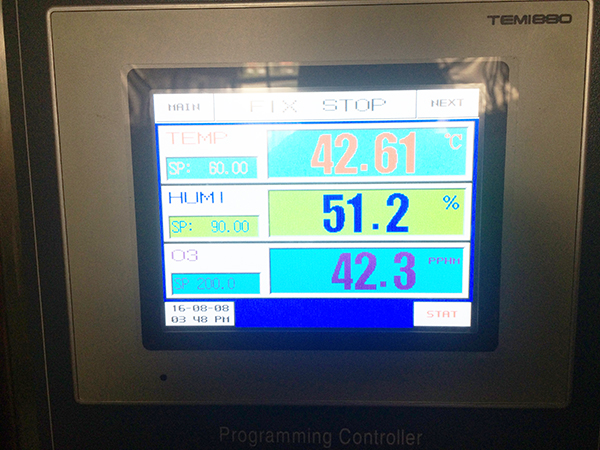

- Environmental Test Chamber

- Tensile Test Equipment

- Paper Packaging Test Equipment

- Furniture Test Equipment

- Vibration Shaker Table Systems

- Textile Test Equipment

- Leather & Shoes Test Machine

- Luggage Test Equipment

- Optical Test Equipment

- Rubber and Plastic Test Equipment

- Cookware Testing Equipment

- Baby Stroller / Bicycle / Toys Testing Machine

- Adhesive Tape Test Equipment

العربية

العربية