UV Weathering Test Chamber

UV aging chamber video

UV aging chamber video  UV aging chamber pdf

UV aging chamber pdf

Product Description:

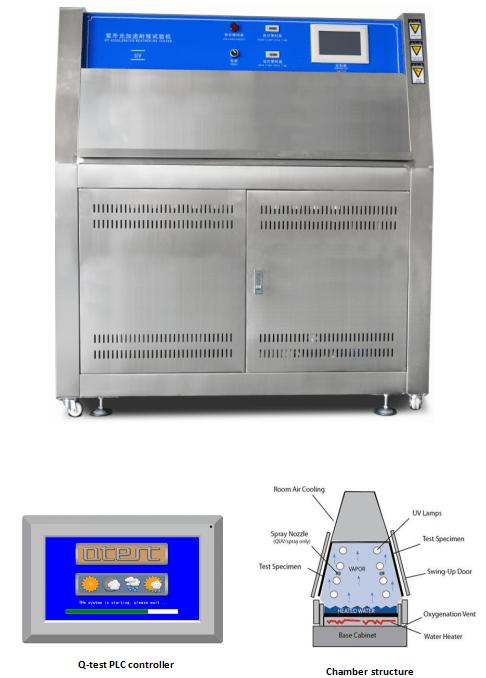

The uv weathering test chamber is widely used to evaluate the weather resistance of materials, and can provide the best sunshine uv,to simulate the sun, rain spray and condensation resulting damage to test the materials by exposure to sunlight with moisture and temperature.

uv weathering test chamber apply to Dyestuff chemical leather shoe material outdoor supplies building materials Home testing organization research and quality control other industries

Features:

Features:

1. Specimen Size: 75×290mm (24pcs) / 75x150mm (48pcs), maximum thickness 5mm

2. Chamber dimension (W*D*H): 1300*500*1460mm

3. Chamber material: SUS#304 stainless steel

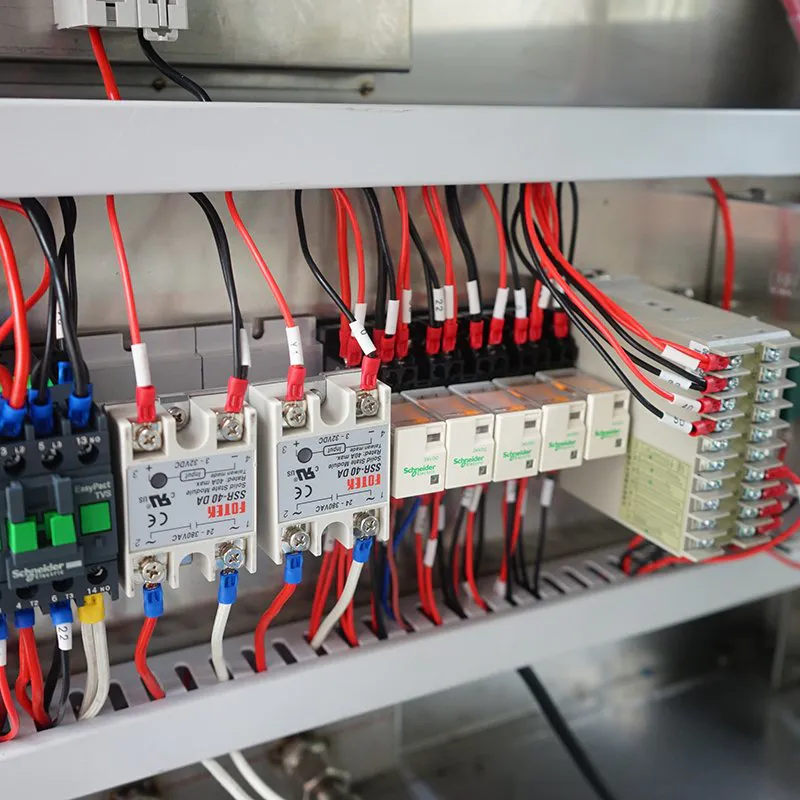

4. Controller: Programmable controller, LCD touch screen

5. Protection system

6. Testing time: 0~999H, adjustable

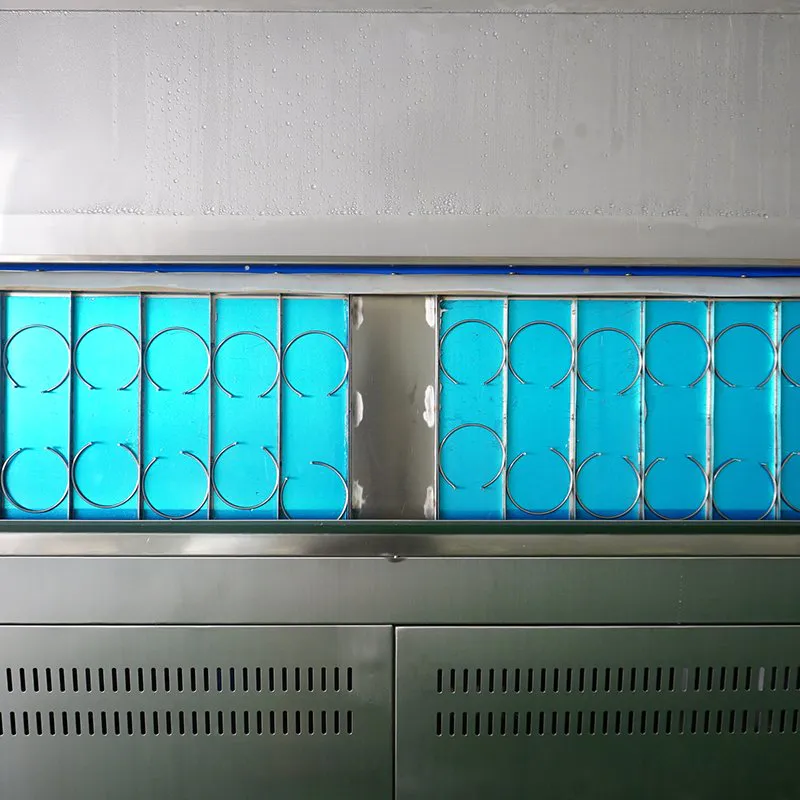

7. UV lamps: Imported Atlas UV-B: 280-315nm (8pcs, 1600h lifetime)

8. Test Criteria:ISO 4892-3,ASTM G154

Applications:

1. Simulate the sun, rain spray and condensation resulting damage to test the materials by exposure to sunlight with moisture and temperature.

2. To get the results of damage after several days or weeks which is equal to expose to outside for a few months. The damages include fading, discoloration, brightness down, powder, crack, blur, brittle, strength decreases and oxidation.

3. Provide reference with testing data for improvement of existing materials, or to assess the impact of changes in product durability and other aspects.

Standard Parameter:

Standard Parameter:

1. Chamber dimension (W*D*H): 1300*500*1460mm

2. Chamber material: SUS#304 stainless steel

3. Temperature range: RT to 70℃

4. Temperature fluctuation: ≤±1.0℃

5. Temperature uniformity: 3℃

6. Humidity range: ≥75%RH

7. Controller: Programmable controller, LCD touch screen

8. Control mode: Balance temperature humidity control (BTHC)

9. Test cycle setting: Exposure, condensation and water spray test cycle is programmable

10. Water spray cycle: Spray 18mins in every 120mins / spray 12mins in every 60mins

11. Water usage: 8L/day

12. Distance from sample to lamp: 55±2mm

13. Centre distance between lamps: 65~70mm

14. Irradiance range: 0.45~0.95W/m2

15. UV lamps: Imported Atlas UV-B: 280-315nm (8pcs, 1600h lifetime)

16. Lamp power: 40W/Piece

17. Specimen Size: 75×290mm (24pcs) / 75x150mm (48pcs), maximum thickness 5mm

18. Testing time: 0~999H, adjustable

UV Lamp:

Fluorescent UV lamps are more stable than other types of tubes (including xenon arc lamps). Spectral power Distribution (SPD) will not change with the aging of the lamp, or even use up to 5000 hours. This will result in more repeatable test results, while reducing the replacement of the lamp and reducing operating costs.

Our Services:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.

1. Pre-service

--24 Hours online service for your consult.

--Help choose right model,and a series of service,person,advise.

2. Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request:

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

3. After sale service :

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Free change for some parts

--Remote control technical consult

--Free installation DVD

--Maintenance plan

4,Commitment:

We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

5,Good Packaging:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

العربية

العربية