Elongation Strength Tester/Universal Testing Machine

Universal Testing Machine Video

Universal Testing Machine Video  Universal Testing Machine Brochure

Universal Testing Machine Brochure

Elongation Strength Tester/Universal Testing Machine have a 2KN (200KG) max testing force capacity for materials which tests is limited as standard,quality,raw materials.

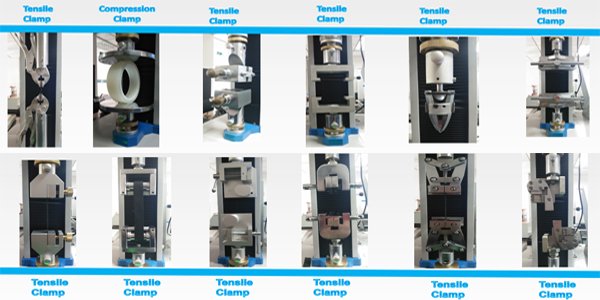

This universal testing machine can do tensile test, tear test, peel test, bond test with different clamps for paper, tape, film,yearn,leather,plastic and other kind of materials.

This Single-screen operation universal testing machine uses the motor to drive screw to move fixtures. Fix sample between upper and lower fixture and pull sample by the upper fixture upward with specified speed. The load cell connecting with upper fixture will sense the force and then convert it into voltage sign to the display screen. Force value will be displayed automatically on the screen.The equipment uses the humanized industrial design, the light weigh, easy to move, can put on the table

1. Tested sample: plastic films, laminated materials, adhesive tapes, adhesive bandage (plaster), release paper, plastic films, leather, rubber & plastic, paper, fiber, etc.

2. Different test with different grips: tensile, peel, tear, heat seal, adhesive, bend and open force.

3. Deformation under defined load: Test deformation under defined load of tested sample

4. Load under defined deformation: Test load under defined deformation of tested sample

5. Universal test software can issue word/excel report with results for max. force, elongation, tensile strength, peel strength, tear strength, compression strength, etc.

Application Standard:

including but not limited to ASTM,JIS,CE, ISO,EN,BS EN,SAE,FTM...etc.

Application Industry :

plastic films, adhesive tapes, adhesive bandage (plaster), paper, plastic films, leather, rubber & plastic, fiber, etc

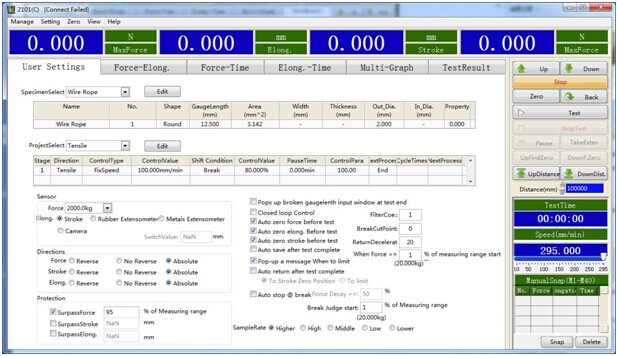

Software

The TM2101 software is designed purposely for computer controlled electronic universal testing machine, used for tension, compress, bend, shear, tearing andpeel test. With the personal computer and interface plate, it could collect, save, process and print test result. Further it can calculate multiple parameters, i.e. maximum force, yield strength, average peel force maximum deformation, yielding point and elastic modulus; this universal testing machine system is featured in curve process, multi-sensor support, image interface, flexible data process and powerful system function.

1. The guarantee period with FOC within 1 year (not including expendable parts cost and transport & travel fees)

1.1 During the guarantee period, Haida shall supply free maintenance or replacement for the damaged part (just for non-expendable part) caused by non-human reasons;

1.2 If any quality problems occur within the guarantee period, and Haida must provide on-site service, the transport and travel expense shall be borne by buyer;

1.3 If any big quality problems occurs out of the guarantee period, Haida will provide a maintain service, the transport and travel expense shall be borne by buyer, also charge for a favorable price for new parts;

1.4 Haida will provide a lifetime favorable price to the buyer for expendable & non-expendable parts used in system operation, equipment maintenance;

2. The following conditions need to be paid reasonably even in the guarantee period:

2.1 Natural disaster

2.2 Operating mistakes

2.3 Voltage is not fit for our manual

2.4 Uninstall without our guides

2.5 Damaged for borrowing to others

2.6 Damaged for without authorized machine modification

2.7 Damaged for without authorized calibration

2.8 Without authorized transshipment mistake

3. Attentions: the machine cannot be used following situations:

3.1 Vibration, rocking place.

3.2 Direct sunlight.

3.3 Hot, dusty, damp places.

3.4 To ensure safe, AC supply of the machine should be well grounded.

3.5 Do not use strong solvents (such as: benzene, nitro oil) washing machine.

3.6 Do not inject water and debris into the machine to prevent damage to electrical components and electrical shock.

3.7 Machine’s disassembly and debugging can only be measured by the State Department approved the units and the company, other people not allowed to overhaul.

العربية

العربية