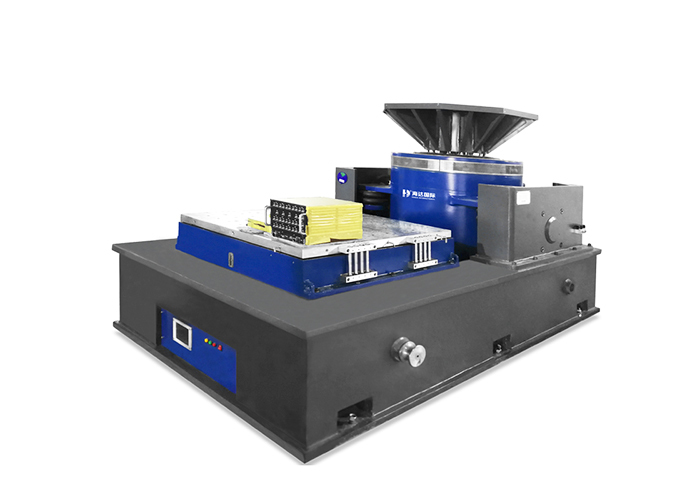

2-axis Vibration Test Systems

Applications:

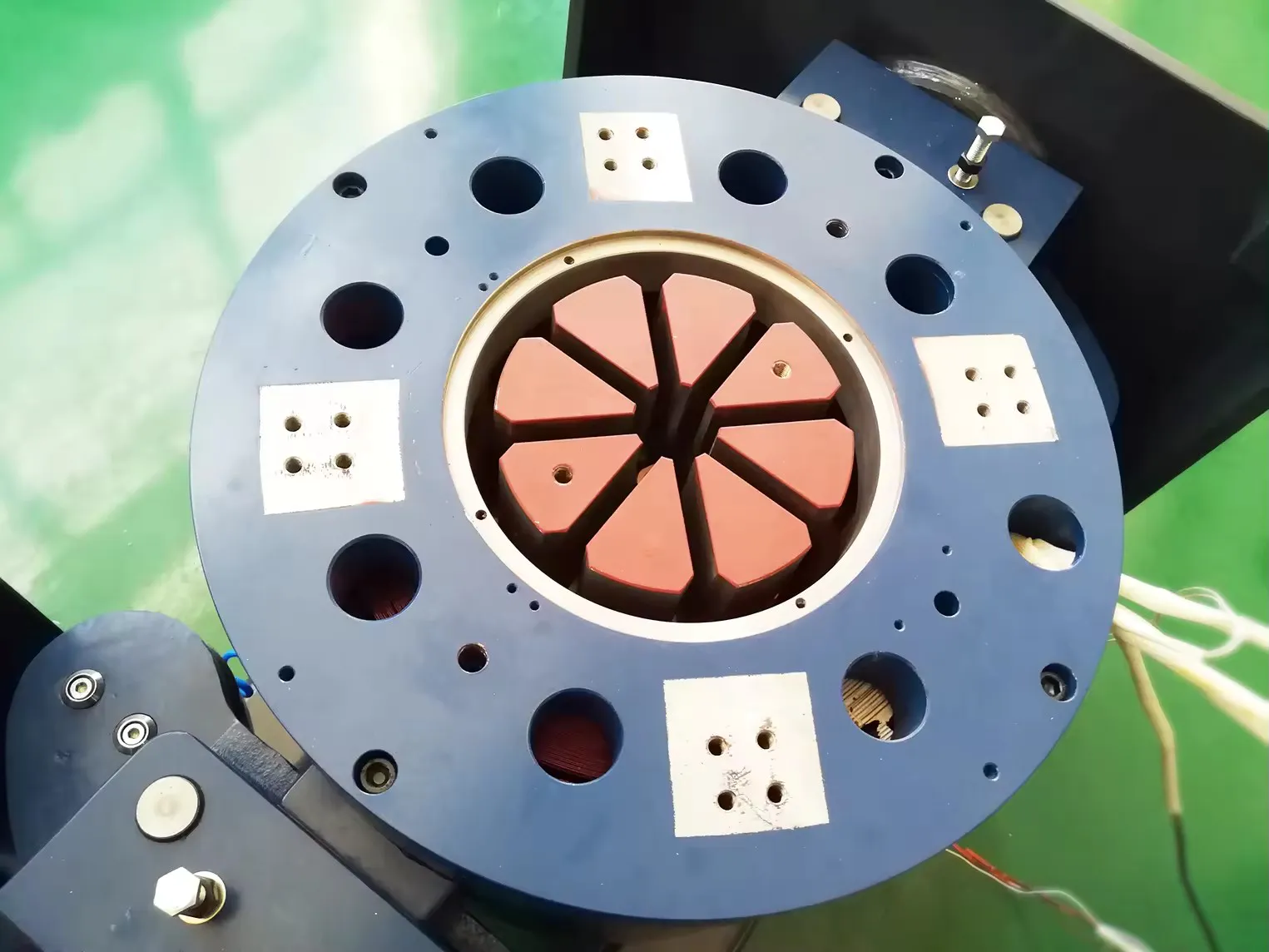

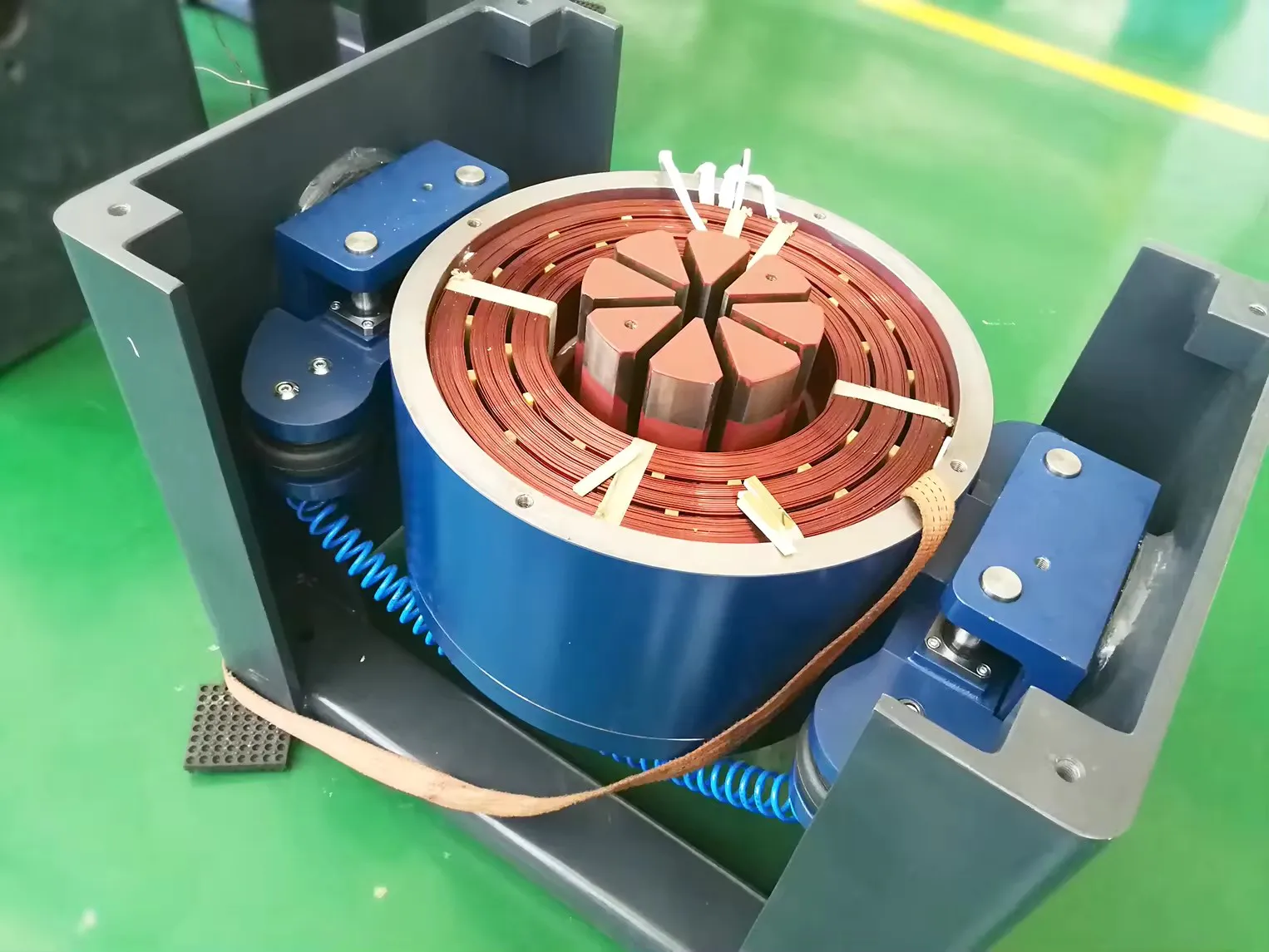

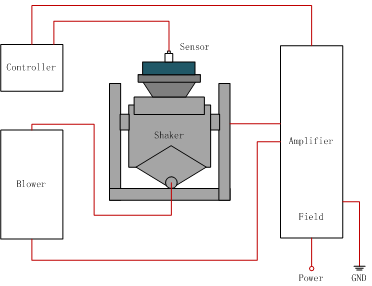

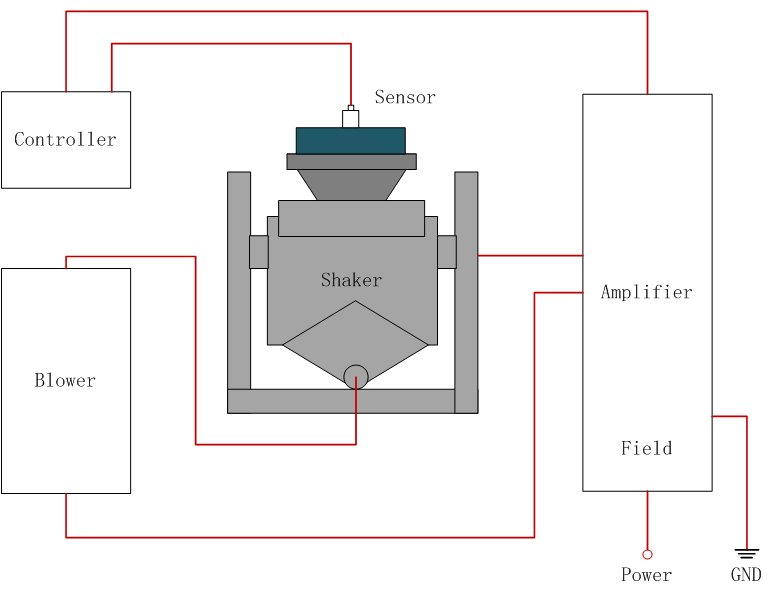

Haida's uniquely-designed Hydrostatic Bearing System minimizes cross-talks among all the axes and also makes the 2-axis Vibration Generators compact. The Systems are capable of 2-axis simultaneous excitation; horizontal (X) and vertical (Z), simulating 'More Real-world Vibration' as it is said that 2-axis excitation can precipitate over 90% of the hidden flaws detectable. In addition to simultaneous excitation, 2-axis Vibration Test Systems have been used for sequential tests of 2 axes thus contributing to time saving and troublesome labor elimination as no vertical & horizontal tables handling and also no specimen unloading & loading are needed, especially employed for transportation tests for large, heavy specimens.

Test standards: MIL-STD, DIN, ISO, ASTM, IEC, ISTA, GB, GJB, JIB, BS, etc.

1. The upper frequency for sine is a frequency up to which the max. force output can be achieved, while that for random is a frequency up to which a PSD random pattern having a -6dB/oct or steeper roll-off over the upper frequency for sine(or lower) can be controlled.

The lower frequencies for control and for excitation are 2Hz and 0.5Hz, respectively unless especially requested.

2. All the Power Amplifiers are of an air cooling type.

3. The HT and LT type systems having a max. force output of 3kN(306kgf), 7kN(714kgf) or 20kN(2,040kgf) are also available.

4. With the employment of the 1-ch Power Amplifiers instead of the 2-ch Power Amplifier, the 2-axis (Automatic) Sequential Vibration Test Systems are also available, which can be upgraded into the Triaxial Simultaneous Vibration Test Systems in the future by adding 1-ch Power Amplifiers and necessary controllers.

5. Vibration Generators with other table sizes than shown above are also available upon request.

6. Power required is 3-phase 200/220/380/415V, 50/60Hz.

7. For better acceleration distribution on the table, the movable weight will be heavier by 10 to 30kg for addition of proper balance weights.

8. For the G-8230 (30kN), air-cooled systems are available upon request.

9. For the air-cooled systems, it is recommended that the hot air from the cooling blower be sent to outside.

10. A System having a bigger force output and/or larger displacement than shown above is also available upon request.

System

Model | Max.

Force

Output | Max.

Accele-

ration | Max.

Velo-

city | Max.

Displace-

ment | Fre-

quency

Range | Table

Size | Mov-

able

Mass | Max.

Pay-

load | Power

Re-

quired | Cooling

System |

Sine

kN (kgf) | Sine

kNrms

(kgfrms) | m/s²(G) | m/s | mmp-p |

Hz

|

Hz

| mm | kg | kg | kVA | [m³ / min]

[L/min] |

HD-G826-1 | 2.9(300) | 1.8(180) | 84(8.6) | 1 | 26 | 1500 | 2000 | 200×200 | 35 | 50 | 17 | Air (16) |

HD-G826-1 | 4.9

(500) | 3.4

(350) | 137(14) | 1 | 26 | 1500 | 2000 | 200×200 | 35 | 50 | 24 | Air(16) |

HD-G826-1 | 62(6.3) | 51 | 1000 | 1500 | 400×400 | 80 | 100 |

HD-G826-1 | 41(4.2) | 800 | 1000 | 600×600 | 120 | 100 |

HD-G826-1 | 3

(300) | 27(2.8) | 500 | 700 | 800×800 | 180 | 200 |

HD-G826-1 | 2.5

(250) | 21(2.1) | 350 | 500 | 1000×1000 | 240 | 200 |

HD-G826-1 | 3.4

(350) | 61(6.2) | 30 | 100 | 700 | 500×500 | 80 | 100 | 18 |

HD-G826-1 | 49(5) | 100 | 500 | 600×600 | 68 | 100 |

HD-G826-1 | 32(3.3) | 100 | 400 | 800×800 | 125 | 200 |

HD-G826-1 | 27(2.7) | 100 | 300 | 1000×1000 | 160 | 200 |

HD-G826-1 | 9.8

(1000) | 6.8

(700) | 284(29) | 1.2 | 26 | 1350 | 2000 | 260×260 | 35 | 100 | 36 | Air(16) |

HD-G826-1 | 127(13) | 51 | 1000 | 1500 | 400×400 | 80 | 100 |

HD-G826-1 | 81(8.3) | 800 | 1200 | 600×600 | 120 | 100 |

HD-G826-1 | 55(5.6) | 700 | 1000 | 800×800 | 180 | 200 |

HD-G826-1 | 5

(500) | 41(4.2) | 350 | 500 | 1000×1000 | 240 | 200 |

HD-G826-1 | 32(3.3) | 300 | 500 | 1200×1200 | 300 | 300 |

HD-G826-1 | 6.8

(700) | 81(8.3) | 1.2 | 51 | 100 | 500 | 600×600 | 120 | 200 | 25 |

HD-G826-1 | 57(5.8) | 100 | 400 | 800×800 | 170 | 200 |

HD-G826-1 | 49(5) | 100 | 300 | 1000×1000 | 200 | 300 |

HD-G826-1 | 36(3.7) | 100 | 200 | 1200×1200 | 270 | 300 |

HD-G826-1 | 19

(2000) | 13.7

(1400) | 326(33) | 1 | 26 | 1200 | 2000 | 320×320 | 60 | 200 | 73 | Air (44) |

HD-G826-1 | 147(15) | 51 | 800 | 1200 | 500×500 | 135 | 200 |

HD-G826-1 | 100(11) | 500 | 1000 | 800×800 | 190 | 300 |

HD-G826-1 | 9.8

(1000) | 68(6.9) | 350 | 500 | 1000×1000 | 290 | 500 |

HD-G826-1 | 52(5.3) | 0.9 | 300 | 350 | 1200×1200 | 375 | 500 |

HD-G826-1 | 34(3.5) | 250 | 350 | 1500×1500 | 565 | 500 |

HD-G826-1 | 13.7

(1400) | 97(10) | 0.9 | 51 | 100 | 400 | 800×800 | 195 | 300 | 40 |

HD-G826-1 | 63(7) | 100 | 300 | 1000×1000 | 300 | 300 |

HD-G826-1 | 47(5) | 100 | 300 | 1200×1200 | 400 | 500 |

HD-G826-1 | 29(2.9) | 100 | 100 | 1500×1500 | 670 | 500 |

HD-G826-1 | 29

(3000) | 20.5

(2100) | 490(50) | 1.1 | 26 | 1200 | 2000 | 320×320 | 60 | 200 | 98 | Air(50) |

HD-G826-1 | 215(22) | 51 | 800 | 1200 | 500×500 | 135 | 200 |

HD-G826-1 | 147(15) | 500 | 1000 | 800×800 | 195 | 300 |

HD-G826-1 | 15

(1500) | 98(10) | 350 | 500 | 1000×1000 | 290 | 500 |

HD-G826-1 | 78(8) | 0.9 | 300 | 350 | 1200×1200 | 375 | 500 |

HD-G826-1 | 52(5.3) | 250 | 350 | 1500×1500 | 565 | 500 |

HD-G826-1 | 49

(5000) | 34

(3500) | 392(40) | 1.3 | 51 | 800 | 1200 | 500×500 | 125 | 300 | 170 | Water(470) |

HD-G826-1 | 245(25) | 700 | 1000 | 800×800 | 200 | 300 |

HD-G826-1 | 25

(2500) | 186(19) | 0.9 | 350 | 500 | 1000×1000 | 270 | 500 |

HD-G826-1 | 79(8.1) | 250 | 350 | 1500×1500 | 620 | 700 |

HD-G826-1 | 70(7.1) | 200 | 350 | 1800×1800 | 700 | 1000 |

HD-G826-1 | 63

(6500) | 44(4550) | 510(52) | 1.4 | 51 | 800 | 1200 | 500×500 | 125 | 300 | 200 | Water(560) |

HD-G826-1 | 294(30) | 700 | 1000 | 800×800 | 200 | 300 |

HD-G826-1 | 32

(3250) | 235(24) | 1 | 350 | 500 | 1000×1000 | 270 | 500 |

HD-G826-1 | 98(10) | 250 | 350 | 1500×1500 | 630 | 700 |

HD-G826-1 | 73(7.4) | 200 | 350 | 1800×1800 | 870 | 1000 |

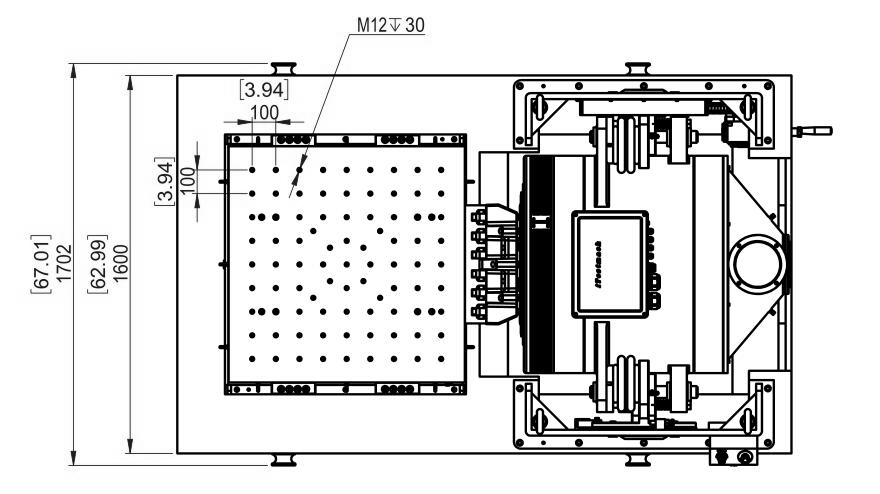

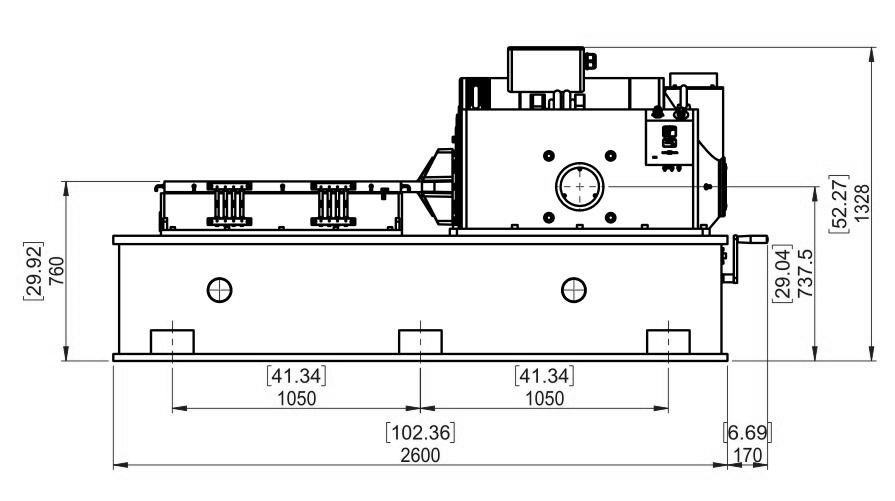

Dimensions for reference only

Dimensions for reference only

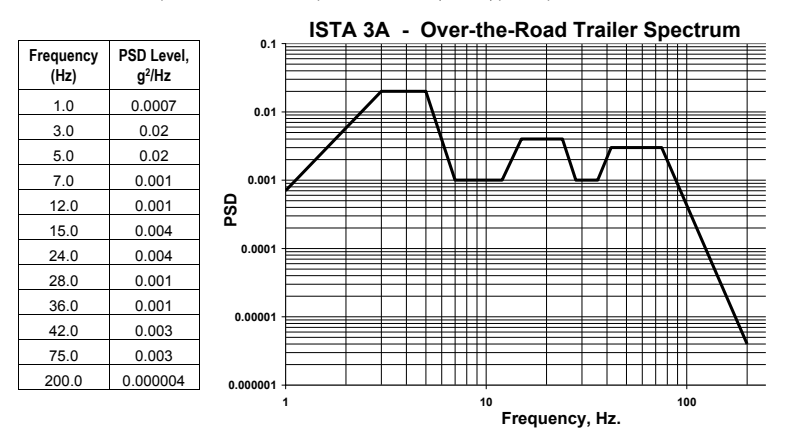

OVER-THE-ROAD TRAILER SIMULATION

The following breakpoints are for an Over-the-Road trailer typical for parcel delivery movement and shall be programmed into the vibration controller to produce the acceleration yersus frequency profile (spectrum) with an overall Grms level of 0.53 (see below). The theorefical stroke required to run this vibrafiun profile is 47.12 mm (1.855 in) peak to peak:

How to use

1. the control manual to complete the procedure

2. such as Operation error so that can not work, you can use the recovery method of the steps of the input, and then set a single group or other running steps.

3. before use to press the external start switch, appears COO namely lets go, opens the key.

4. Taiwan Body:

1) The table body foot sleeve as far as possible fixed

2) power supply on/work in the output line can not be unplugged

3) Place the level as far as possible

4) components can be changed, the line should not be changed or from the connection.

5) The Taiwan body must not be all or part of the reorganization, only according to specifications for a single component and with the original confirmation password.

5. the amplitude inside the code

1) Do not adjust too large before or after the boot

2) low-key amplitude of high amplitude modulation

3) Control Panel Amplitude Knob placed in the middle position test items: placed to focus on the main point, reduce the left flat right.

4) control Box: Can not be placed on the top or underground operation

6. Inside Code:

1) reset when running or operating incorrectly

2) Control The Reset method step, each inside code only set one time to save can

3) usually must use the internal code can not be set randomly

7. Control Box:

1) The connecting line of the body must be locked tightly after hanging

2) the vibration direction switch and the output connection line are correspondence, can not connect the wrong

8. testing: Non-special test should use full wave test

9. the Taiwan body: can not produce the collision sound, the upper and lower center axis mutual touch will cause the spring steel piece rupture to be immediately shut down, amplitude modulation is adjusted small then turns on.

10. other unknown:

Do not arbitrarily change internal components and lines

11. the reason is bad:

1) The use of computer models can not be used for shaking table control

2) can not reload the driver

12. for the Ista-ia test, the operator to protect the sample, to prevent the test pieces slide out of the table;

13. gear gearbox replacement regularly;

14. Cut off all power when not working, keep clean; 5, non-staff can not operate at will;

العربية

العربية