Haida test equipment obtained certificate of new high-tech enterprise in 2019 Phone:+86-13602361535 E-mail:manager@qc-test.com

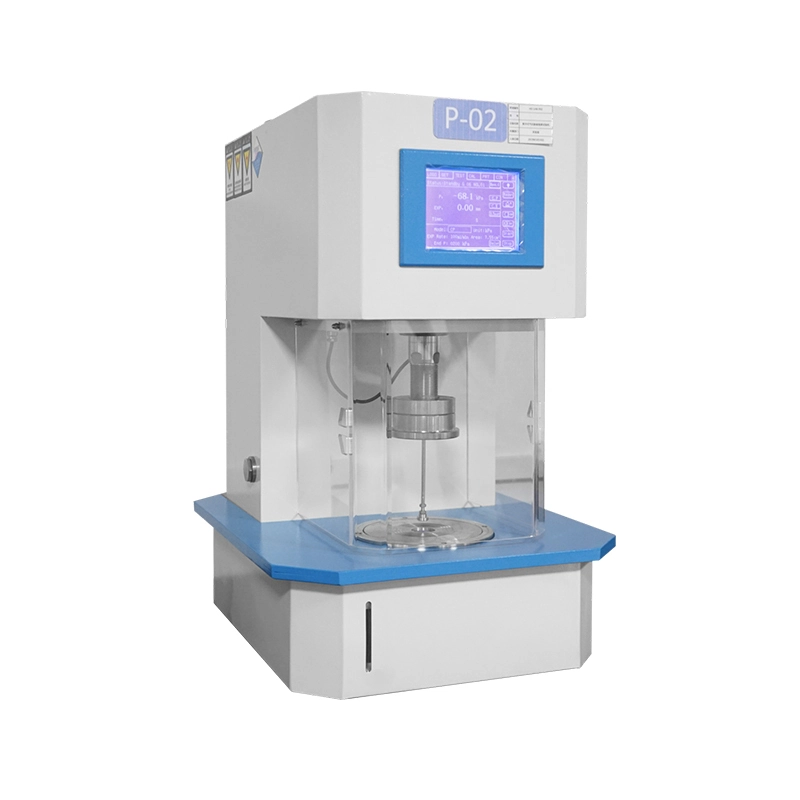

Automatic Hydraulic Bursting Tester

Introduction

Textile fabrics having no particular directions cannot be tested its strength via tensile testers;

a multi-directional force generated by hydrostatic pressure is applied on fabric to check the strength of that

fabric, this phenomenon is called bursting strength testing. Automatic Hydraulic Diaphram Bursting Tester is specially designed to perform the bursting strength testing of kitted fabrics, with pneumatic control.

It can also be used for leather, paper & card Boards etc.

Test Kit 50cm² Test Kit 7.55cm²

Usage

To determine the bursting strength and distension at burst of woven and knitted fabrics as well as technical textiles,non-wovens,bonded fabrics,plastics,leather (artificial and natural) and cardboard.

Testing standard

ASTM D 3786 Standard Test Method for Hydraulic Bursting Strength of Textile Fabrics

Diaphragm Bursting Strength Tester Method

BS 4768 Determination of Bursting Strength and Bursting Distension

ISO 13938-1 Textiles - Bursting properties of fabrics, Hydraulic method for determination of bursting strength and bursting distension

ISO 2758 Paper - Determination of bursting strength

ISO 2759 Board - Determination of bursting strength

ISO 3303 Rubber - or plastics-coated fabrics - Determination of bursting strength - Hydraulic method

WSP 030.1.R3(12),BS 3424(PT6),ERT 80-4-20,EN 12332-2,IWS TM 29,ASTM D751,JIS L-1018

Test procedure

The Burst Tester is designed for measuring the bursting strength of fabric materials subjected to an increasing hydrostatic pressure. This pressure is applied to a circular region of the specimen via an elastic diaphragm. The specimen is firmly held round the edge of this circular region by a pneumatic clamping device. When the pressure is applied, the specimen deforms together with the diaphragm. The bursting strength corresponds to the maximum pressure supported by the specimen before failure. Identical, in the principle to the multi-directional tensile test, Ball Burst Method for Fabrics, this measurement is independent from the cutting direction of the sample (machine or cross) since the failure naturally occurs in the least resistance direction.

Technical details

Areas of Application | Textiles:Knitted and woven apparel, Technical textiles Nonwovens:Wet wipes, surgical gowns/masks Plastics:Food packaging, bin liners, sacks and various plastic products Medical:Organ patches, hernia patches, wound dressings, animal skin Paper:Kitchen paper, Toilet tissue, Other paper products |

Pressure measurement range | 2000kPa, L/C : 1kPa |

Distension measurement range | Up to 75 ± 0.02 mm |

Measuring areas | 7.55cm² (Ø 31mm) and 50cm² (Ø 79.8mm) |

Unit of measurement | kPa - kgf/cm² - mmHg - lb/in² - atm |

Test methods | Constant Rate - Constant Pressure - Constant Distension –Timing |

Hydraulic system rate of flow (adjustable) | 20-600mL/min |

Hydraulic oil | Glycerine 85%, distilled water 15% |

Safety sensor | Over scale auto-stop |

Diaphragm rubber thick | ≤ 2 mm |

Data port | RS232 port for printer connection and 3 pin Mini-DIN connector for PC |

Dimensions | 550 x 450 x 700 mm |

Power supply | 220V,50Hz |

Air requirements | 600-800kPa |

Weight | 125kg |

Accessories supplied with the instrument

1.Main Unit:01 No.

2.Test Kit 7.55cm² (Ø 31mm) and 50cm² (Ø 79.8mm):01 No.(each)

3.Synthetic Rubber Diaphragms(Maufacturer:James Heal):02 Nos.

4.Diaphragm Unit Tightening wrench:01 No.

5.Air Pipe (To connect with compressor):01 No.

6.Glycerol (500mL):01 No.

7.USB software:01 No.

8.Power Cord:01 No.

9.This User’s Manual:01 No.

10. Inspection & Conformance Certificate:01 No.

TOUCH CONTROL PANEL

Leave A Message

HAIDA Test Equipment

Contact us

Contact: Mrs. Zhong

WeChat: haida13602361535

E-mail: manager@qc-test.com

Phone: +86-13602361535

Add: Room 101, Building 3, No. 1, Dongwei 1st Road, Wanjiang Street, Dongguan City, Guangdong Province, China