Haida test equipment obtained certificate of new high-tech enterprise in 2019 Phone:+86-13602361535 E-mail:manager@qc-test.com

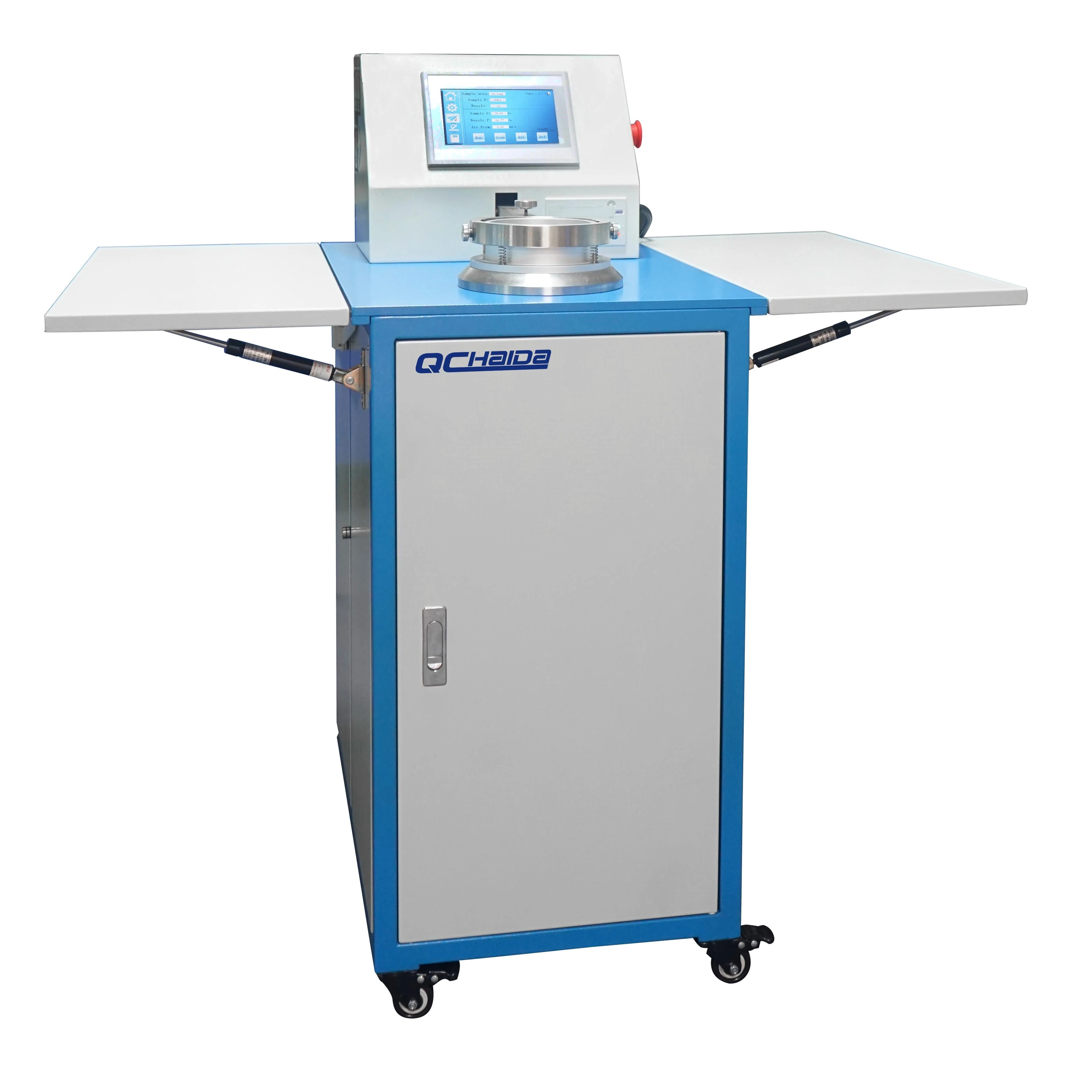

Air permeability testing equipment for textile

Air permeability testing equipment for textile

APPLICATION

Air permeability ,also as a kind of textile testing equipment,is an important factor in the performance of such textile materials as gas filters, fabrics for air bags, clothing, mosquito netting, parachutes, sails, tentage, and vacuum cleaners. In filtration, for example, efficiency is directly related to air permeability. Air permeability also can be used to provide an indication of the breathability of weather-resistant and rainproof fabrics, or of coated fabrics in general, and to detect changes during the manufacturing process. In specialty, industrial and military applications, Air permeability testing equipment can play a vital role in protection. In every market, satisfying the demands of consumers and producers requires ways to accurately and repeatably test material air flow.

USAGE

Air permeability testing equipment To determine the resistance of fabrics (woven, knitted and nonwoven textile materials) to the passage of air (air flow) under constant pre-set air pressure while firmly clamped in the test rig of selected test head/area.

TEST STANDARD:

ASTM D737 Standard Test Method for Air Permeability of Textile Fabrics

ISO 9237 Textiles - Determination of the Permeability of Fabrics to Air

BS 5636, DIN 53887, AFNOR G07-111, EDANA 140.1, ISO 7231, ISO 9073-15, JIS L1096-A

TAPPI T251, WSP 070.1.R3, EDANA 140.2-99

STANDARD FEATURES

Measuring range | 0.1-12,000 mm/s at 20 cm² test area. |

Units of measure | mm/s, ft³/ft²/min, cm³/cm²/s, l/m²/s, l/dm²/min, m³/m²/min, m³/m²/h, dm³/s Pa (pressure drop) |

Measuring accuracy | better than ± 2 % of the displayed value. |

Test pressure | 1-4,000 Pa |

Test areas | 5, 20, 25, 38.5 and 100 cm² |

Sample thickness | 0 ... 12mm |

Dimensions | 1070 x 670 x 1080 mm |

Power supply | 220V, 50Hz or 110V, 60Hz |

Weight | 75kg |

TEST PROCEDURE

1.Test the conditioned specimens in the standard atmosphere for testing textiles, which is 21 ± 1°C (70 ± 2°F) and 65 ± 2 % relative humidity, unless otherwise specified in a material specification or contract order.

2. Handle the test specimens carefully to avoid altering the natural state of the material.

3. Place each test specimen onto the test head of the test instrument, and perform the test as specified in the manufacturer’s operating instructions.

4. Place coated test specimens with the coated side down (towards low pressure side) to minimize edge leakage.

5. Make tests at the water pressure differential specified in a material specification or contract order. In the absence of a material specification or contract order, use a water pressure differential of 125 Pa (12.7 mm or 0.5 in. of water).

6.Read and record the individual test results in SI units as cm³/s/cm² and in inch-pound units as ft³/min/ft² rounded to three significant digits.

SALIENT FEATURES

1. Wide measuring range of 0.1-12,000 l/m²/s at 20 cm² test area.

2. Wide test pressure range of 1-4,000 Pa.

3. For filter media: Determination of the pressure drop at a given air velocity.

4. Automatic control of the test pressure.

5. Fast and simple sample clamping(Pneumatic Clamping Assembly).

6. Touch control panel for digital display of the test result.

7. Quiet and mobile instrument, perfectly suitable for use in the laboratory and in the production area.

8. Data ports: RS 232. Ethernet for direct network access.

9. Integrated software for evaluation and storage of the test results in office format.

10. Can be connected to a PC with the Evaluation Program SBT461 Air Permeability Tester lab-cloud.

11. Works in accordance with all major test standards.

ACCESSORIES SUPPLIED WITH THE INSTRUMENT

1. Main Unit: 01 No.

2. Test Heads: 02 Nos.

20 cm²for DIN 53887, EN ISO 9237, WSP 70.1

38.5 cm²for ASTM D 737, JIS L 1096-A, TAPPI T 251, WSP 70.1

3. SBT461 Air Permeability Tester lab-cloud: 01 No.

4. Calibration Check Plate: 02 Nos. (ΦO=7.8 and ΦO= 21.6)

5. O-Ring for Air Seal: 01 No. (pack of 5)

6. Nozzle: 11 Nos.

No. | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

ΦO(mm) | 0.8 | 1.2 | 2 | 3 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

7. Power Cord: 01 No.

8. This User’s Manual:01 No.

9. Inspection & Conformance Certificate: 01 No.

view:

Leave A Message

HAIDA Test Equipment

Contact us

Contact: Mrs. Zhong

WeChat: haida13602361535

E-mail: manager@qc-test.com

Phone: +86-13602361535

Add: Room 101, Building 3, No. 1, Dongwei 1st Road, Wanjiang Street, Dongguan City, Guangdong Province, China