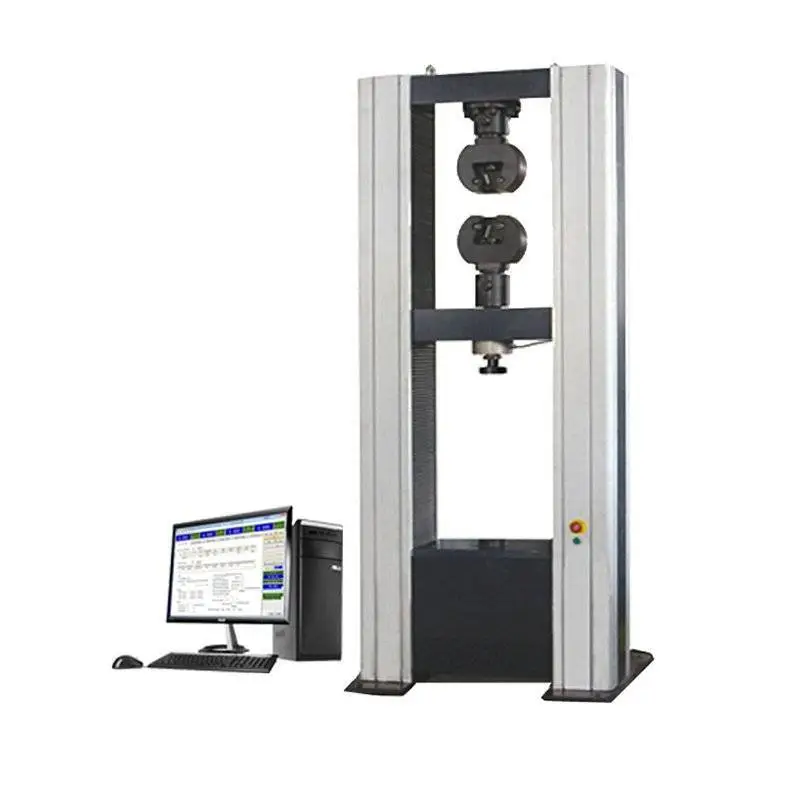

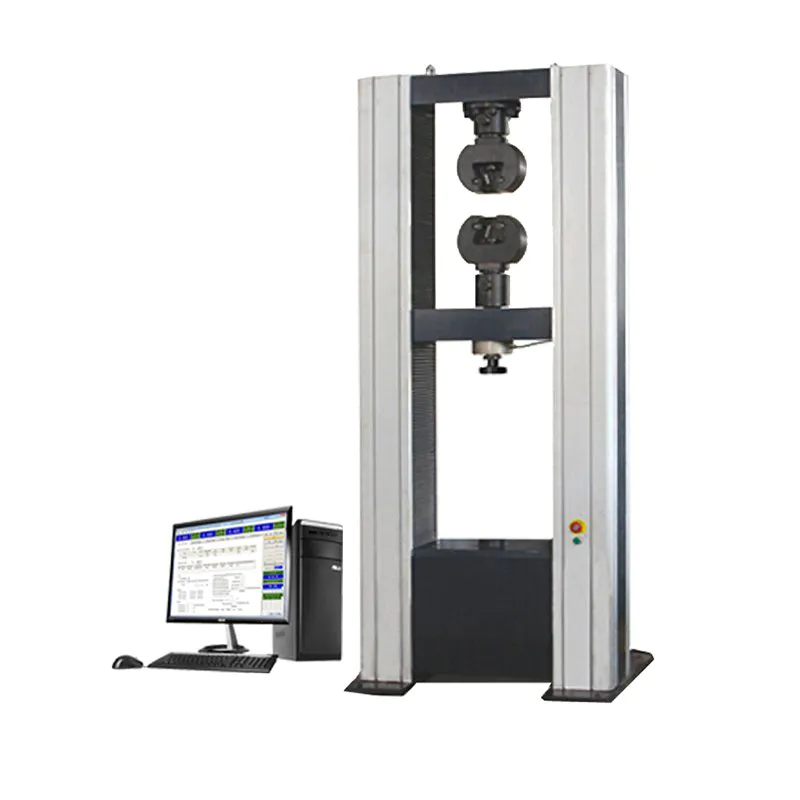

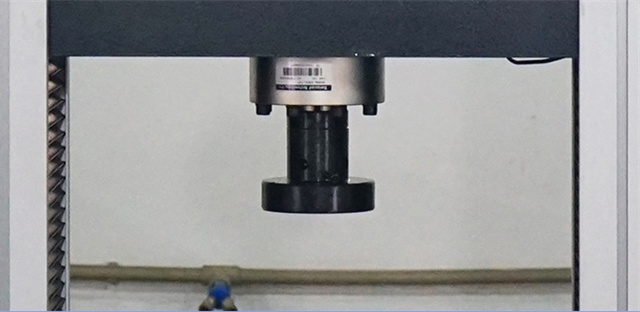

This type universal testing machine have a strong power (10T max force and 2T, 5T are optional).10T test capacity universal test machine is particularly design to use for metal,steel,plastic pipe, etc with specialized sensors and fixtures. The data will be displayed on the computer so that the force values change during the test.

Rubber

Spring

Wood

Plastic

Application Standard:

Including but not limited to ASTM,JIS,CE, ISO,EN,BS EN,SAE,FTM...etc